Difference between revisions of "Technical Specifications"

Jump to navigation

Jump to search

Efeinblatt (talk | contribs) |

Efeinblatt (talk | contribs) |

||

| Line 6: | Line 6: | ||

|- | |- | ||

| | | | ||

| − | [[File:Banana-fiber layered.png| | + | [[File:Banana-fiber layered.png|thumb|''Banana fiber layered between plastic'']] |

| − | || | + | || |

| + | [[File:Composite sheet.png|thumb|''Single composite sheet after heating & pressing'']] | ||

|- | |- | ||

| − | | | + | | |

| + | [[File:Multiple composite sheets.png|thumb| Multiple sheets cut and pressed together | ||

| + | ]] | ||

| + | || | ||

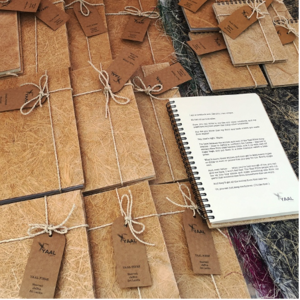

| + | [[File:Notebook.png|thumb|Notebook: final product]] | ||

|- | |- | ||

| − | + | ||

| − | |||

| − | |||

|} | |} | ||

Revision as of 11:21, 20 November 2020

A brief technical overview of processes and protocols for composite manufacturing from plastic waste (LDPE, HDPE, etc.) reinforced with fibers (cardboard, agricultural waste, textile, woodchips, etc.)

The processes for creating a composite sheet or tile, which is the base material from which both domestic (notebooks, wallets, clipboards, coasters, lampshades, etc.) and building (ceiling tiles, roofing tiles, piping, etc.) products are manufactured are essentially identical: they both require equipment that exerts heat and pressure.