Technical Specifications

A brief technical overview of processes and protocols for composite manufacturing from plastic waste (LDPE, HDPE, etc.) reinforced with fibers (cardboard, agricultural waste, textile, woodchips, etc.)

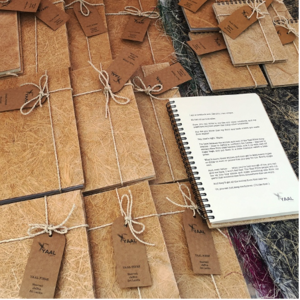

The processes for creating a composite sheet or tile, which is the base material from which both domestic (notebooks, wallets, clipboards, coasters, lampshades, etc.) and building (ceiling tiles, roofing tiles, piping, etc.) products are manufactured are essentially identical: they both require equipment that exerts heat and pressure.

For domestic products, a simple, commercially available laminating, tee-shirt or sublimation heatpress is adequate. The press can be manually operated or pneumatically powered, which is preferable but requires a more robust electrical infrastructure. For this project, we recommend the manual press. The single difference between the heatpresses we use and the ones that are most commonly available is that both the top and bottom platens of our preferred presses contain heating elements, so the base material (combination of plastic and fiber) is heated from above and below. Additional equipment may include a shredder/grinder (depending on the quality of the plastic and/or fiber) and a heat sealer (to seal the edges of certain products, i.e. wallets and bags.)

Building material requires equipment that produces sheets or tiles much like those used for domestic products, however, because the structural properties of those tiles must be significantly enhanced compared to the domestic tiles, the machinery – which produces higher pressure and heat – is more sophisticated. These machines are custom made to our specifications and require a complex infrastructure to support their operation. We are not considering this for the purposes of the Tijuana project.

We recommend the DC16 heatpress for the Tijuana project. It is manufactured in the US by GEO Knight & Co. in Massachusetts, and they have a distributor, Forever America, (tel: (55) 5586 6896) in Mexico. There is also a California distributor, Conde Systems, (tel: 800-826-6332). We have installed the pneumatic version of this press at USD and the Kumeyaay reservation in Viejas.

| DC 16 Heatpress | Specifications |

|---|---|

| 120 Volts/1500 Watts/12 Amps

14in x 16in dual-heated platens 135 lbs + 30 lbs for bottom heated platen $1295 - DC16 https://www.heatpress.com/products/digital-combo-14x16 $775 - DCA-1416BHT (bottom heated platen and control) https://www.heatpress.com/products/bottom-heat-fixture $295 – DKA Universal Stand https://www.heatpress.com/products/dk-universal-stand The total amperage required will be 24 Amps due to the addition of the bottom heated platen |

A granulator/grinder such as the Prosino PS-C-M (https://www.sinoshredder.com/shredders/small-sized-plastic-granulator/) is within our budget, but we need to source something similar in Mexico. Just learned that they actually have a distributor in Mexico: NOVAEPRESS INDUSTRIAL S DE RL DE CV Martiniano Dominguez Gamez No. 100 Colonia Buenavista, Zumpango. Estado de México. CP.55600 México Tel: 52+ 591-9185921 Contact: Vanessa Mendoza

Room requirements are minimal. 25m2 with window ventilation can easily accommodate a Prep Station, Cooling Station and Heatpress Work Station.